Original Event Date: April 12, 2004.

Chicago, IL — April 12, 2004:

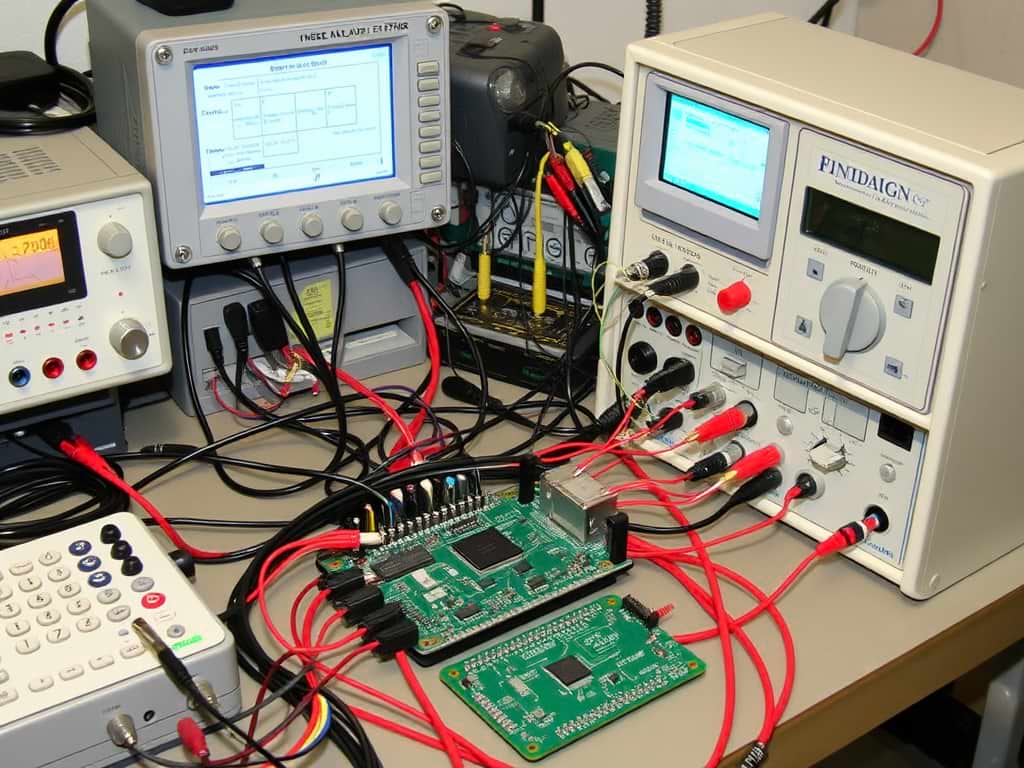

In a step forward for off-grid solar power research, HiGrow has officially rolled out its new load cycling inverter testing program aimed at evaluating the long-term durability of early-stage inverter prototypes. This innovative testing method reflects HiGrow’s ongoing dedication to developing reliable renewable energy systems for rural and remote applications.The load cycling inverter testing setup, introduced in Q1 of 2004, allows HiGrow engineers to simulate months of real-world use within a compressed time frame. By exposing early inverter models to alternating high and low electrical loads, the team can track system behavior under stress — including voltage waveform consistency, thermal expansion, and component drift.

At this stage, HiGrow’s inverter designs are intentionally simple — targeting 300W to 1200W output ranges, with minimal digital control and a focus on rugged, analog reliability. These off-grid inverters are meant for basic setups such as lighting, fan use, and appliance charging in underserved power zones.

“This form of testing is essential if we want to deliver affordable, trustworthy systems to regions without grid access,” explained a HiGrow project engineer. “It lets us predict and prevent failure scenarios long before deployment.”

The test benches now include automated relay-based load control, passive cooling setups, and detailed sensor logging. As results accumulate, engineers are refining transformer coil designs and capacitor selections to improve overall system stability.

HiGrow plans to utilize insights from this load cycling inverter testing phase for its upcoming pilot programs in late 2005. The goal is clear: ensure that every inverter sent into the field has been stress-tested for real-world conditions — even in the absence of advanced monitoring software.